Chain Slings

Chain Slings

Why Trinity Chain Slings?

Trinity Sling offers both mechanical and welded chain sling assemblies. All overhead lifting chain slings are made to the standards of ASME B30.9.

Mechanical chain slings are the most flexible and cost-effective chain slings, and they are also faster and easier to repair or modify to meet customer needs. Trinity Sling is proud to use and distribute Columbus McKinnon (CM) chain and chain sling components for its overhead lifting chain slings. CM chain and chain components are Made in America.

Verification and Tracking

Overhead lifting chain slings must be made from grades 80, 100 or 120 to meet ASME B30.9 standards. All three of the grades of chain are marked directly on the links for grade verification. All chain slings are tagged with a Working Load Limit (WLL) that includes a minimum 4 to 1 design factor. Trinity Sling’s durable tags show all relevant WLL’s, have a unique serial number, and have an RFID chip, as well, for InfoChip integration.

Periodic Inspection and Recertification

Overhead lifting chain slings require a periodic inspection. Trinity Sling recommends that all chain slings used for overhead lifting be inspected and recertified on an annual basis at minimum. Trinity Sling’s chain sling re-certification process includes a link by link inspection and proof test that assures all chain slings will perform according to their design factors. The periodic inspection is also a good time to make certified repairs and modifications.

Chain Sling Specs

| DESIGN FACTOR | 1 LEG SLINGS | 2 LEG SLINGS | 3 LEG AND 4 LEG SLINGS | ||||||

| 90° | 60° | 45° | 30° | 60° | 45° | 30° | |||

| Grade 120 Alloy Temperature Resistance | |||||||||

| 9/32” | 5200 | 9000 | 7400 | 5200 | 13500 | 11000 | 7800 | ||

| 3/8” | 10600 | 18400 | 15000 | 10600 | 27500 | 22500 | 15900 | ||

| 1/2” | 17900 | 31000 | 25300 | 17900 | 46500 | 38000 | 26900 | ||

| Grade 100 Alloy | |||||||||

| 7/32” | 2700 | 4700 | 3800 | 2700 | 7000 | 5700 | 4000 | ||

| 9/32” | 4300 | 7400 | 6100 | 4300 | 11200 | 9100 | 6400 | ||

| 5/16” | 5700 | 9900 | 8100 | 5700 | 14800 | 12100 | 8500 | ||

| 3/8” | 8800 | 15200 | 12400 | 8800 | 22900 | 18700 | 13200 | ||

| 1/2” | 15000 | 26000 | 21200 | 15000 | 39000 | 31800 | 22500 | ||

| 5/8” | 22600 | 39100 | 32000 | 22600 | 58700 | 47900 | 33900 | ||

| 3/4” | 35300 | 61100 | 49900 | 35300 | 91700 | 74900 | 53000 | ||

| 7/8” | 42700 | 74000 | 60400 | 42700 | 110900 | 90600 | 64000 | ||

| 1” | 59700 | 103400 | 84400 | 59700 | 155100 | 126600 | 89550 | ||

| Grade 80 Alloy | |||||||||

| 7/32” | 2100 | 3600 | 3000 | 2100 | 5500 | 4400 | 3200 | ||

| 9/32” | 3500 | 6100 | 4900 | 3500 | 9100 | 7400 | 5200 | ||

| 5/16” | 4500 | 7800 | 6400 | 4500 | 11700 | 9500 | 6800 | ||

| 3/8” | 7100 | 12300 | 10000 | 7100 | 18400 | 15100 | 10600 | ||

| 1/2” | 12000 | 20800 | 17000 | 12000 | 31200 | 25500 | 18000 | ||

| 5/8” | 18100 | 31300 | 25600 | 18100 | 47000 | 38400 | 27100 | ||

| 3/4” | 28300 | 49000 | 40000 | 28300 | 73500 | 60000 | 42400 | ||

| 7/8” | 34200 | 59200 | 48400 | 34200 | 88900 | 72500 | 51300 | ||

| 1” | 47700 | 82600 | 67400 | 47700 | 123900 | 101200 | 71500 | ||

| 1-1/4 | 72300 | 125200 | 102200 | 72300 | 187800 | 153400 | 108400 | ||

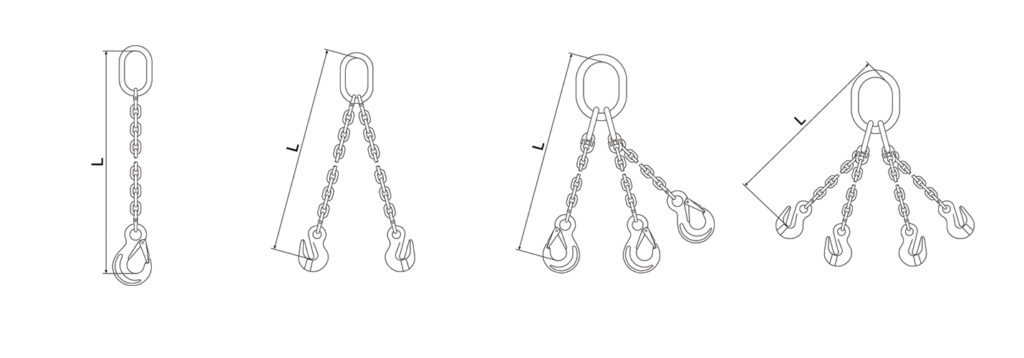

Reference: Above Drawings – Pewag Industrial Catalog # IND08, Copyright © by pewag International GmbH. All rights reserved, worldwide.

Reference: Chart Grade 120 – Pewag Industrial Catalog # IND08, Copyright © by pewag International GmbH. All rights reserved, worldwide.

Reference: Chart Grade 100 and Grade 80 – Chain and Rigging Attachments (CMRP-6) Catalog, © 2017 Columbus McKinnon Corporation.