Wire Rope Fittings

Wire Rope Fittings

Wire Rope End Fittings

End Fittings: Swage Sockets, Spelter Sockets and Threaded Ends

Large structures and equipment needing stabilization and support require specially-fabricated wire rope products. These assemblies usually fit swaged or poured terminations to wire rope. Assemblies like these used on boom cranes are referred to as either pennant or boom lines. Similarly-made products are also frequently used in structures such as large awnings and support cables for bridges.

END FITTING MEASUREMENTS MATTER

The proper application of these types of assemblies requires careful consideration of capacity, length, plane, and type of termination. The capacity of the socketed assembly will be determined by the diameter and grade of wire rope. Trinity Sling offers a wide variety of wire ropes suitable for socketed and threaded wire rope terminations. The length of a socketed or threaded wire rope assembly requires exacting measurements. These usually are ordered in pairs and require length matching. Due to the differences in stretch inherent in different batches of wire rope, it is not recommended that new socketed slings be matched to used assemblies. The lengths will be mismatched under load.

TRINITY KNOWS SOCKET TERMINATIONS

At Trinity Sling we have years of experience with the various types of socket terminations. The terminations most commonly come with one of three types of connections; open socket (female), closed socket (male), and threaded ends. An open socket looks like a fork with a pin that can be inserted to close and secure the end fitting to the opening of the fork. A closed socket has an eye. The eye of the closed socket is designed to accept the pin of the open socket so they can be linked together. Threaded wire rope end fittings can be made with any type of thread pitch or thread length required for the application.

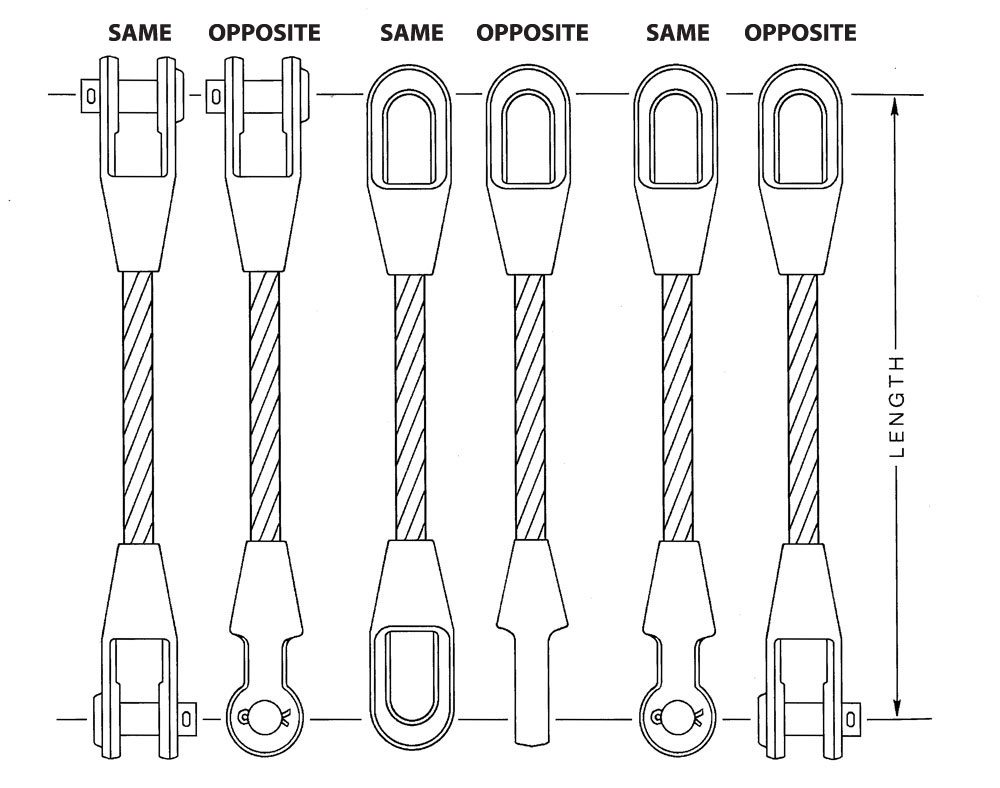

With open and closed socket wire rope terminations the plane of the attachment to the wire rope is also important. The plane of the assembly is determined by the degree relative to each end to which the terminations are attached. Consult the diagram from the Wire Rope Sling User’s Manual for reference to same and opposite planes.

POURED SOCKETS

IWRC & Fiber Core

Drawing: Wire Rope Sling User’s Manual, Third Edition © 2007, p.49.)

WELL-BUILT SOCKET ASSEMBLIES DEPEND ON EXPERIENCE

Whether a job requires poured sockets or swaged sockets, well-built assemblies will carry up to 98% of the rated break strength of the rope. Poured sockets are usually set with an epoxy covering the broomed wires inside the socket, while swaged end fittings are attached by forming the shank of the end fitting over the wire rope with a press. Poured socket wire rope end fittings feature flexibility of assembly.

With a properly-trained person and the right equipment, poured sockets can be made in the field. Field installation should not be used in critical or overhead lifting or supporting applications, however, as those applications cannot be proof tested in the field.

TRINITY SLING—THE SOURCE FOR END FITTINGS

As for all products fabricated by Trinity Sling we use only the highest quality materials and industry-recommended manufacturing techniques for our end fittings. Trinity Sling’s high capacity test bed is available for proof loading and recertification of all type of pennant lines and socketed end fittings. Trinity Sling can also offer tagging and asset tracking of each assembly with the InfoChip tagging and tracking system.

With the assistance of our trained sales personnel Trinity Sling can help design and fabricate specialty swaged end fittings to meet your specific needs. Such specialty end fittings are often used in military applications or in specialty manufactured goods. Trinity offers a wide variety of custom and standard fittings to accommodate most any rigging situation. Rigging experts with decades of experience in the industry are available Monday through Friday from 8-5 CST to answer questions, provide quotes, or satisfy hard-to-fill spec requirements for jobs across the U.S. and Canada, often from existing inventory. Call 1-877-589-2404 for more information or to place an order.

End Fitting Photo: Muncy-Catalog_2013 Page 10, Copyright © 2017 Muncy Industries. All rights reserved.